Monitor, analyze, and improve your robotic

workcells with high performance 3D graphics

Revolutionize Data Monitoring

Monitor, analyze, and improve

your robotic workcells with

high performance 3D graphics

Revolutionize

Data Monitoring

of your factory's data

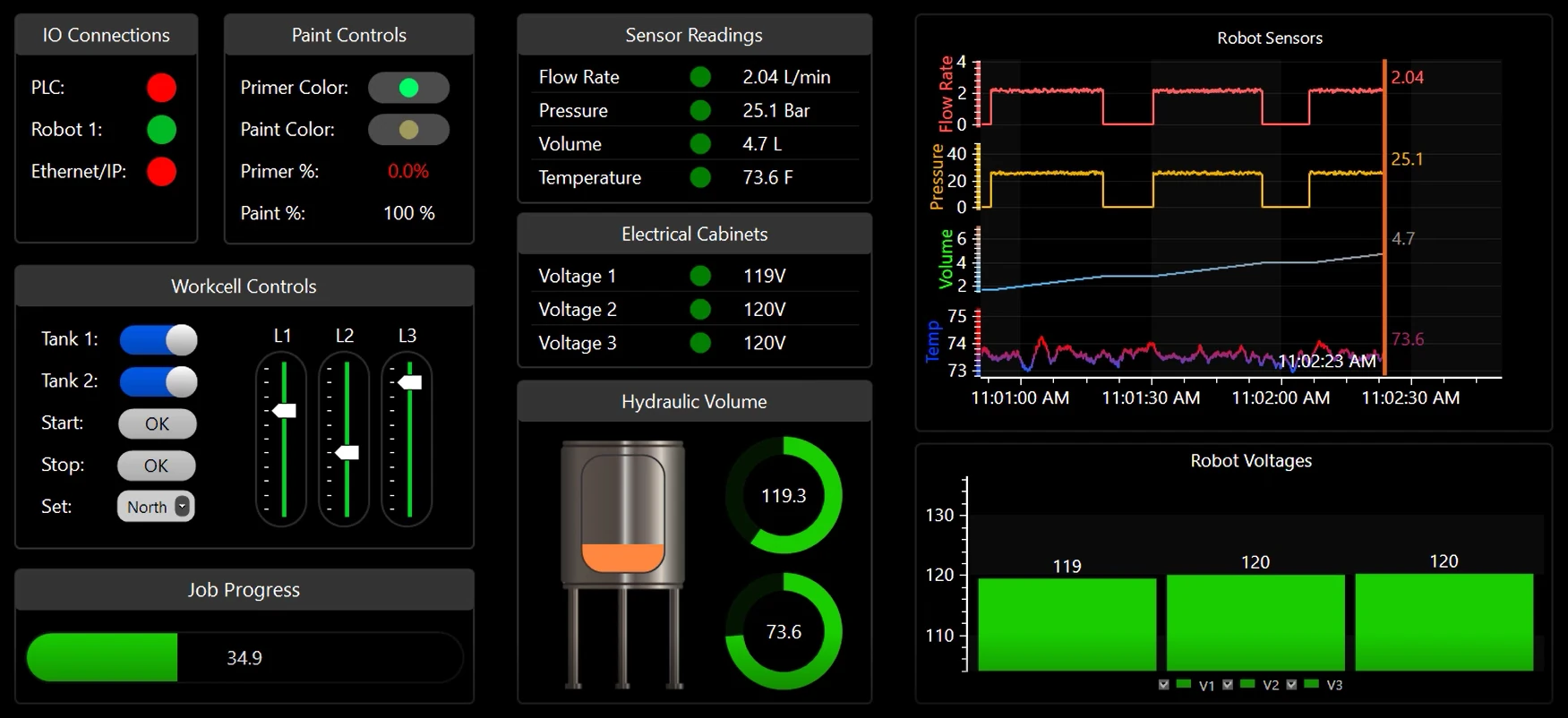

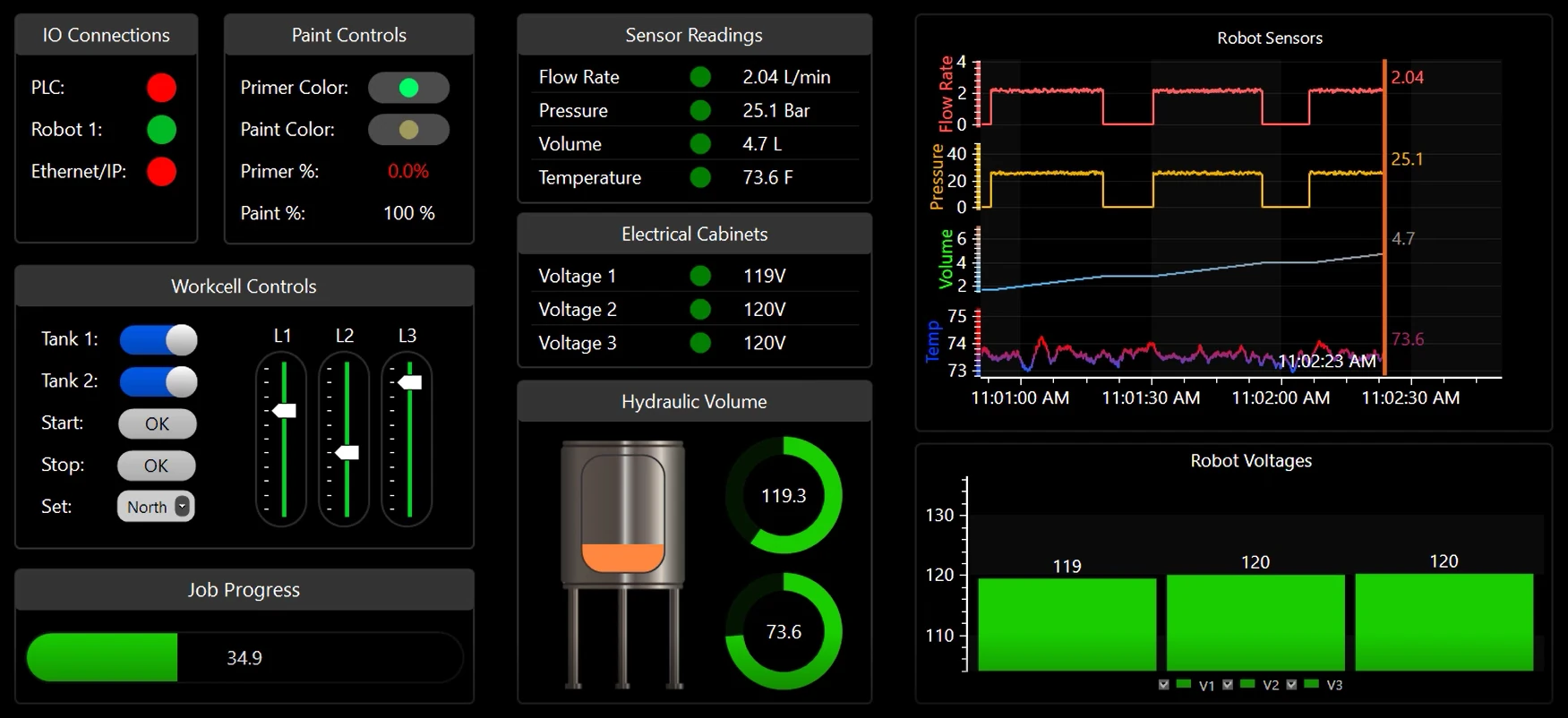

• Monitor production with a feature rich 2D dashboard

• View metrics from your desk or your phone

• Track alarms, measure downtime, and get events on your phone

• Unmatched performance with hardware accelerated graphics

Monitor From Anywhere

• Monitor production with a

feature rich 2D dashboard

• View metrics from your

desk or your phone

• Track alarms, measure downtime,

and get events on your phone

• Unmatched performance with

hardware accelerated graphics

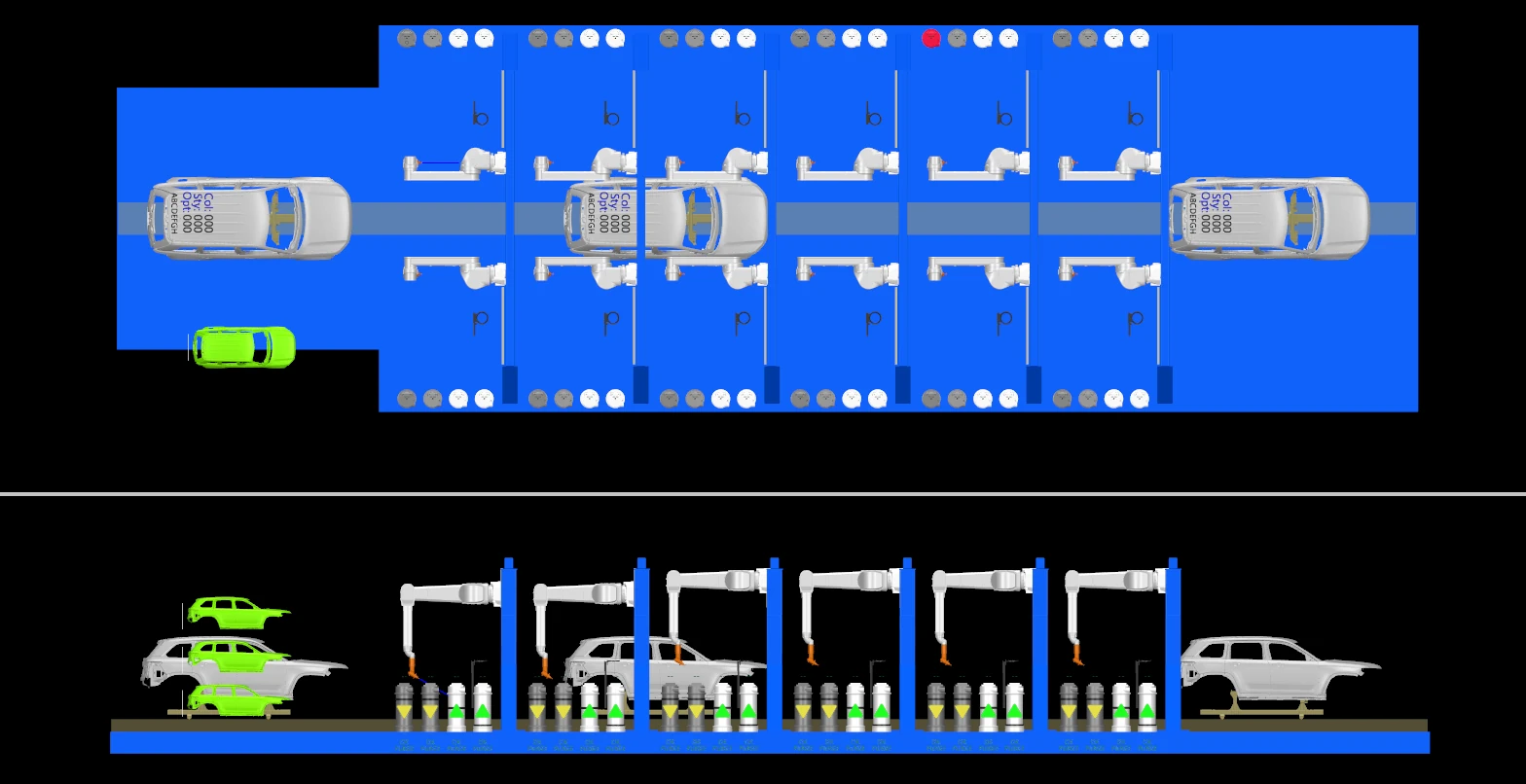

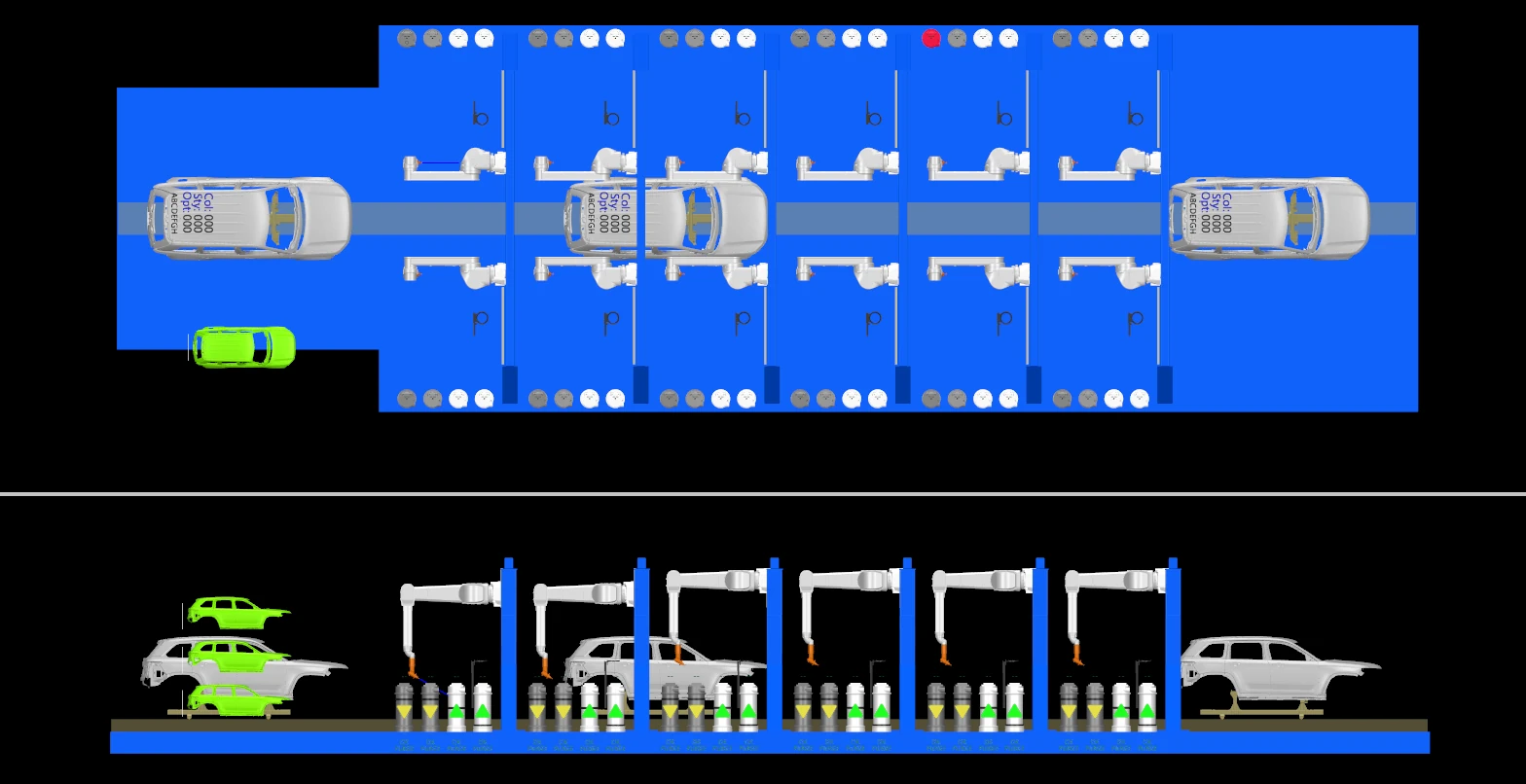

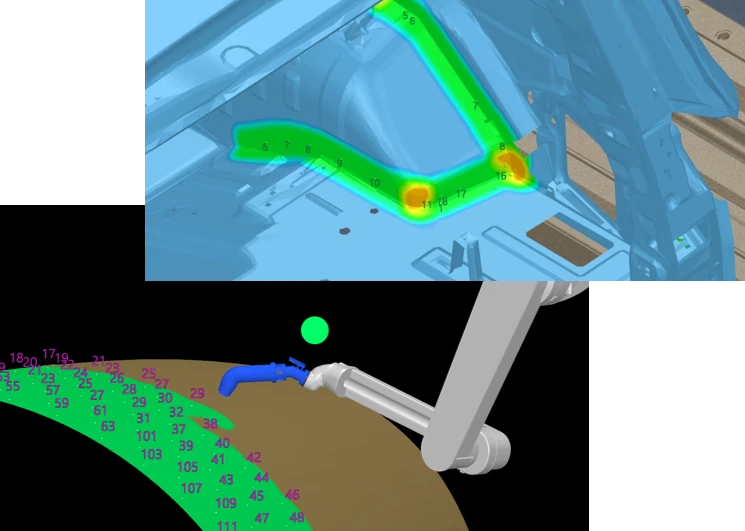

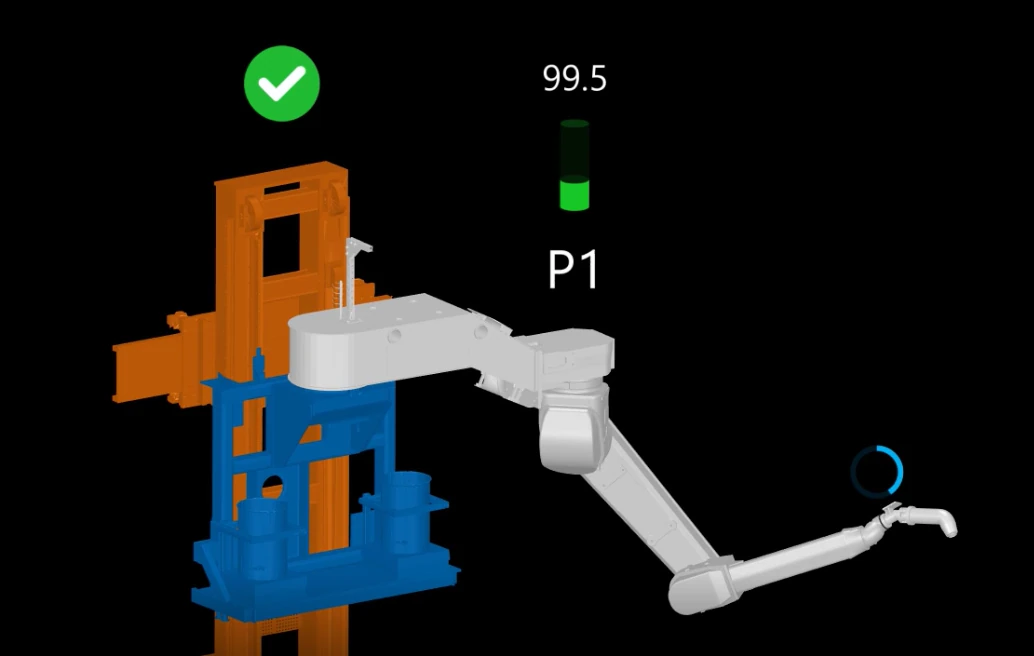

• Monitor production in real-time with 3D views

• Attach floating metrics to moving robots and parts

• Quickly associate alarms with specific robots and machines

• Track robot work progress in 3D

Real-Time 3D

• Monitor production in real-time

with 3D views

• Attach floating metrics to

moving robots and parts

• Quickly associate alarms with

specific robots and machines

• Track robot work progress in 3D

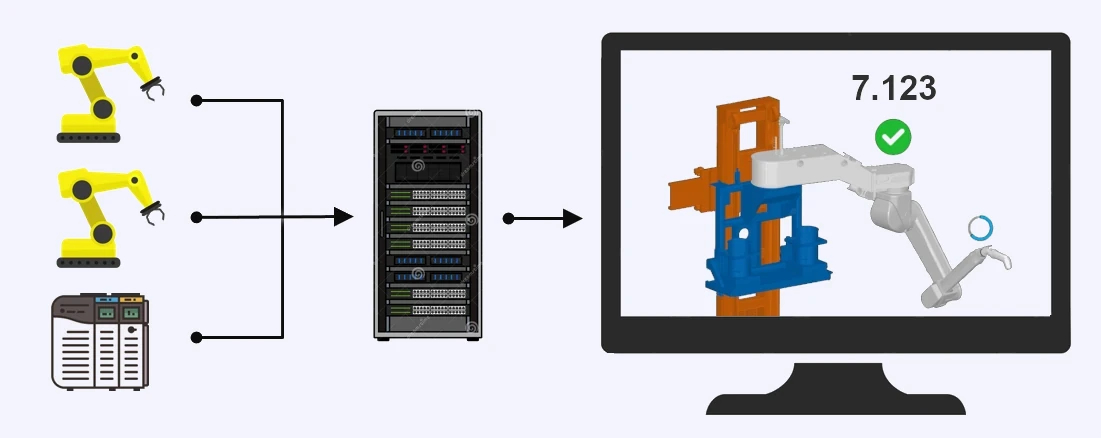

• Collect robot data with a click of a button

• Easily access data in PLCs and other industrial devices

• Track alarms, measure downtime, and get events on your phone

• Connections are easy to set up, performant, and network efficient

Tap into Existing Data

• Collect robot data with

a click of a button

• Easily access data in PLCs

and other industrial devices

• Track alarms, measure downtime,

and get events on your phone

• Connections are easy to set up,

performant, and network efficient

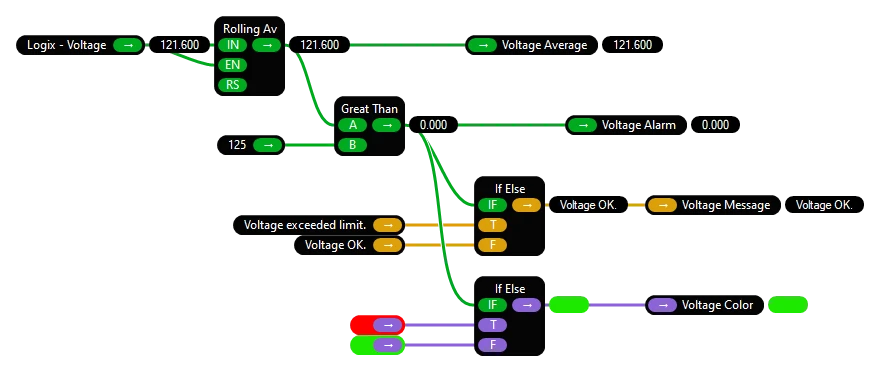

• Simplify analysis with drag-and-drop programming

• Visual programming style can be mastered by anyone

• Perform common logic as well as advanced statistics

• Optimize production speed, efficiency, and throughput

Analyze Data with Ease

• Simplify analysis with

drag-and-drop programming

• Visual programming style

can be mastered by anyone

• Perform common logic

as well as advanced statistics

• Optimize production speed,

efficiency, and throughput

• Record and playback events in 3D using MotionView historian

• Best-in-class compression reduces data storage by 90 percent

• Extremely simple data search and query tools

• Troubleshoot events like never before with complete 3D playback

Record and Playback

• Record and playback events in

3D using MotionView historian

• Best-in-class compression

reduces data storage by 90%

• Extremely simple data

search and query tools

• Troubleshoot events like never

before with 3D playback

1

3

4

5

2

Tap into existing

factory data within

robotic workcells

Monitor production

in real-time using

3D technology

Perform analysis,

improve production,

and reduce downtime

Playback historical

data using a

live 3D stream

Record data in

an enterprise

level database

How Does it Work?

How Does it Work?

2

Record data in

an enterprise

level database

1

Tap into existing

factory data within

robotic workcells

3

4

5

Monitor production

in real-time using

3D technology

Perform analysis,

improve production,

and reduce downtime

Playback historical

data using a

live 3D stream

Remotely monitor the shop floor from your desk in 3D.

Crucial for systems with

limited line of sight.

Troubleshoot faster with simple data analysis tools combined with historical playback in 3D.

Improve preventive maintenance and forecasting by analyzing part processing times

and failure rates.

Reduce network congestion

and data storage costs

with best-in-class data

compression algorithms.

Immediate feedback and analysis leads to optimizing

production and

reducing bottlenecks.

Identify patterns and

anomalies in production quality.

Track quality metrics over time for better quality control.

Maximize Visibility

Improve Quality

Increase Throughput

Operate Efficiently

Speed Troubleshooting

Reduce Downtime

Benefits

Benefits

Remotely monitor the shop floor from

your desk in 3D.

Crucial for systems with

limited line of sight.

Troubleshoot faster with simple data analysis tools combined with historical playback in 3D.

Maximize Visibility

Speed Troubleshooting

Improve preventive maintenance and forecasting by analyzing part processing times

and failure rates.

Troubleshoot faster with simple data analysis tools combined with historical playback in 3D.

Reduce Downtime

Improve Quality

Immediate feedback and analysis leads to optimizing

production and

reducing bottlenecks.

Reduce network congestion

and data storage costs

with best-in-class data

compression algorithms.

Increase Throughput

Operate Efficiently

• Enterprise time-series database allows for factory wide scalability

• Record and display millions of data points per second

• Compatible with third-party database analysis tools

• Reduce data storage costs by 90% with best-in-class compression

Enterprise Level Database

• Enterprise time-series database

allows for factory wide scalability

• Record and display millions of

data points per second

• Compatible with third-party

database analysis tools

• Reduce data storage costs by 90%

with best-in-class compression